What It Does:

-

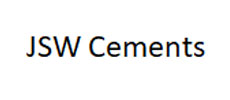

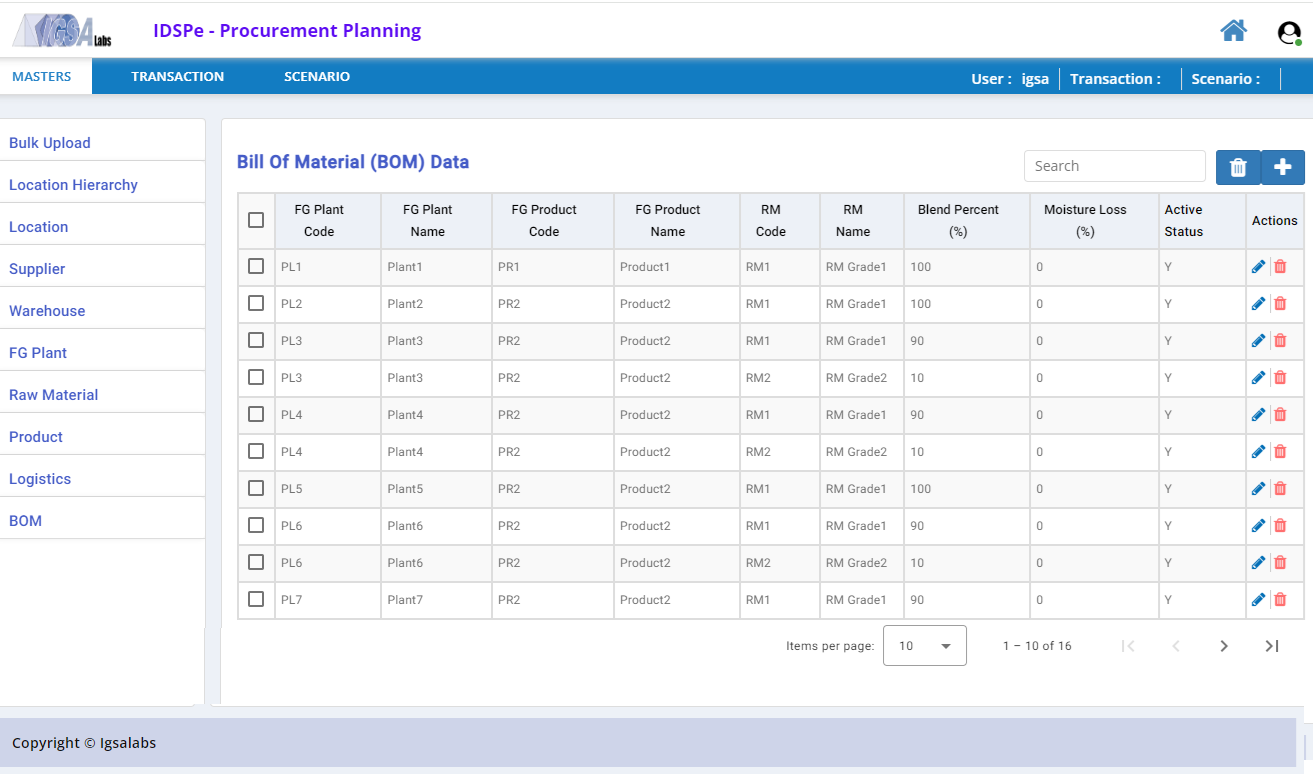

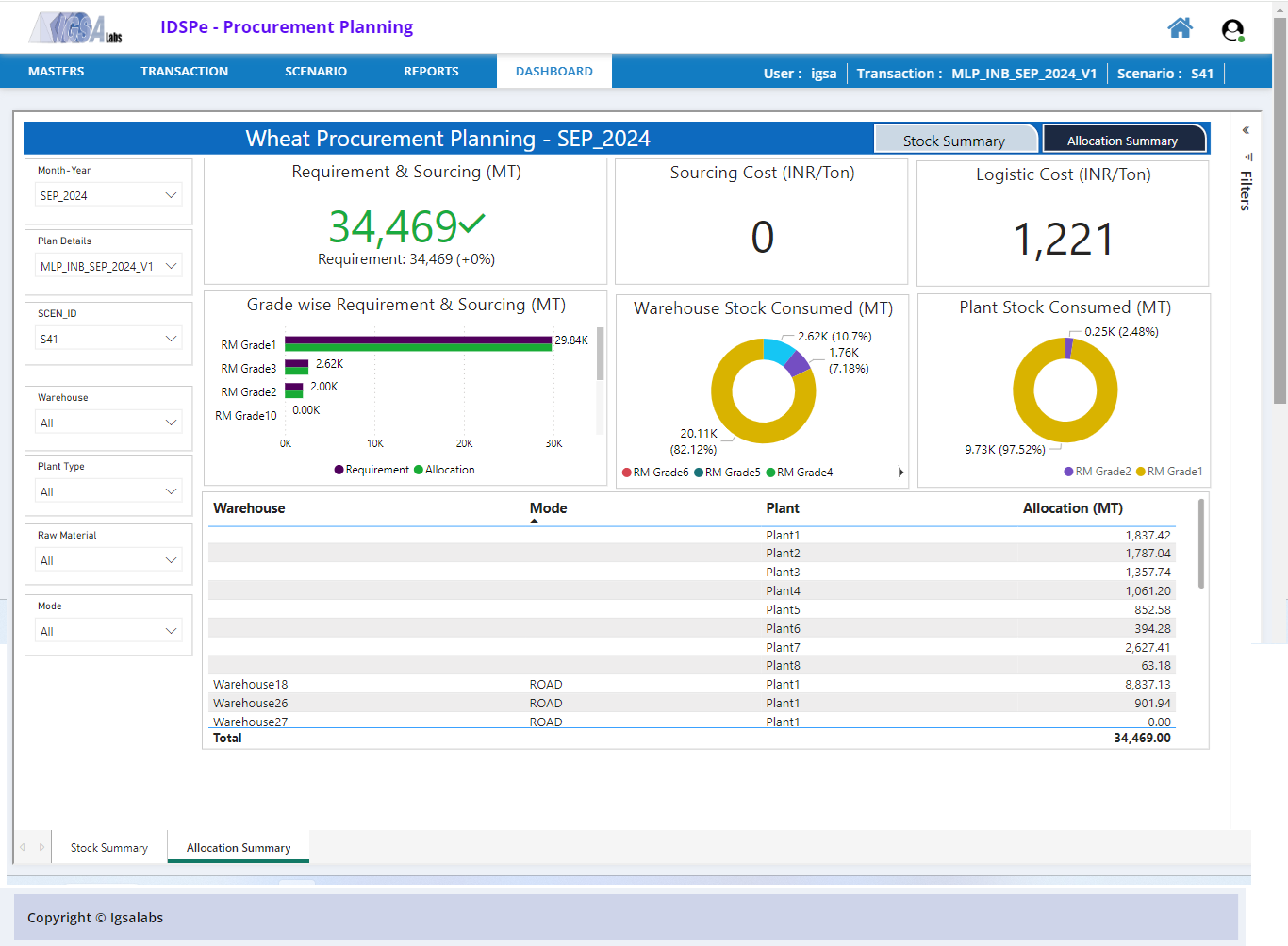

Create optimal plan for procuring raw materials, parts and components from supplier facilities to customer facilities (plants) in order to meet production plans for finished products

-

Minimize landed cost (procurement and inbound shipment costs) and inventory carrying of raw materials/parts/components subject to meeting plant-wise production plans, requirements as per bill-of-materials, safety stock targets, share-of-business and other terms of supplier contracts, and achieving high utilization of production assets

-

Run large scale mixed-integer linear programming model with millions of variables in quick time

-

Facilitate ‘what-if’ analysis with multiple scenarios

-

Validate input data, resolve infeasibilities, and display violations of production plans, supplier contract terms, capacity and other constraints

-

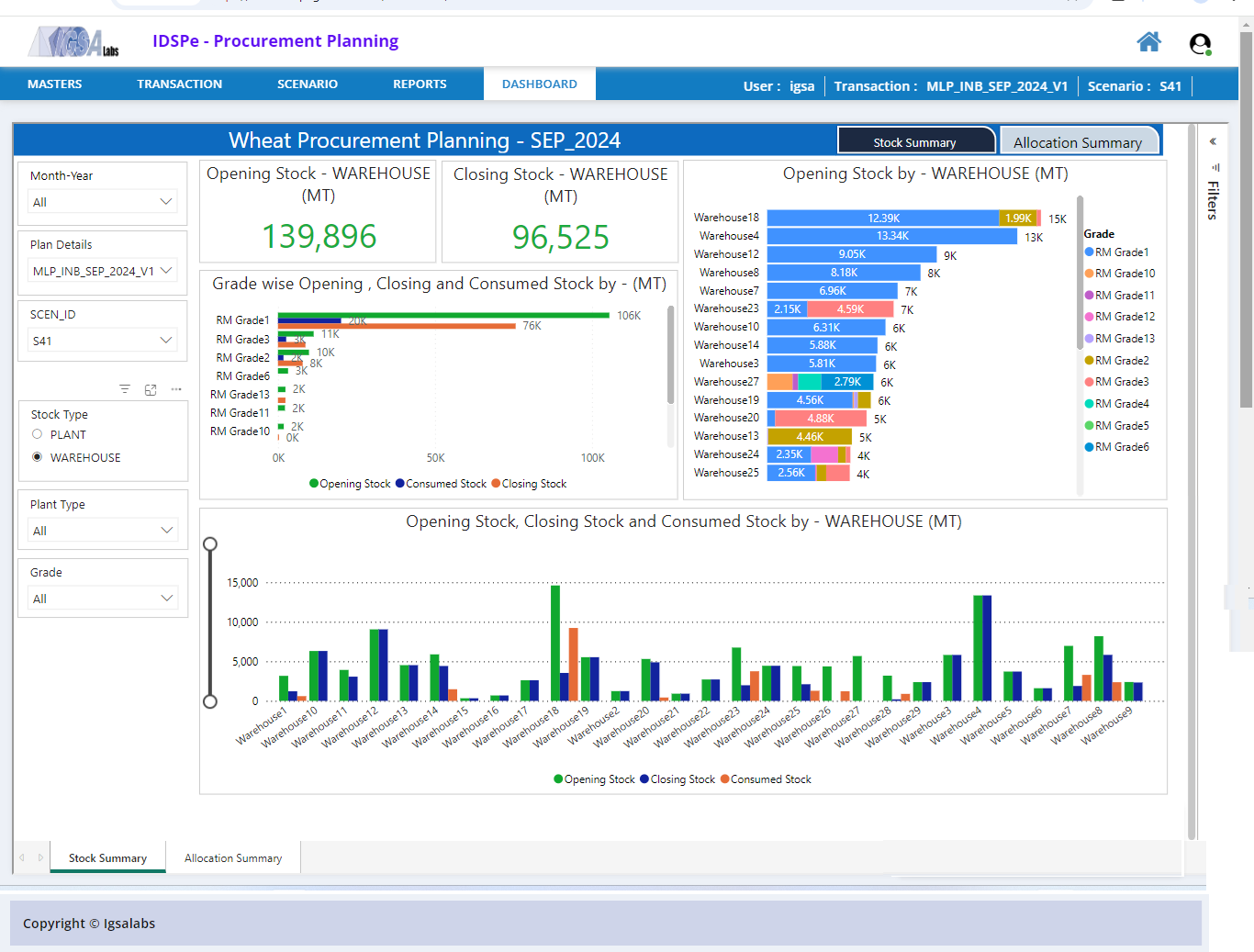

Report performance metrics such as production requitement fulfillment rate, procurement and inbound transportation costs, inventory carrying cost, utilization of production assets

-

Align procurement, production and logistics teams with common business objectives and facilitate inter-functional collaboration

Analytical Models and Techniques

-

Large-scale mixed-integer linear programming (MILP)

-

Algorithms for ‘what-if’ scenario analysis

Tools and Technologies

-

MILP models with GAMS and CPLEX

-

Input data interface with Java

-

Dashboards for reports and collaborative platform with Power BI and Java

Case Studies

Clients