What It Does:

-

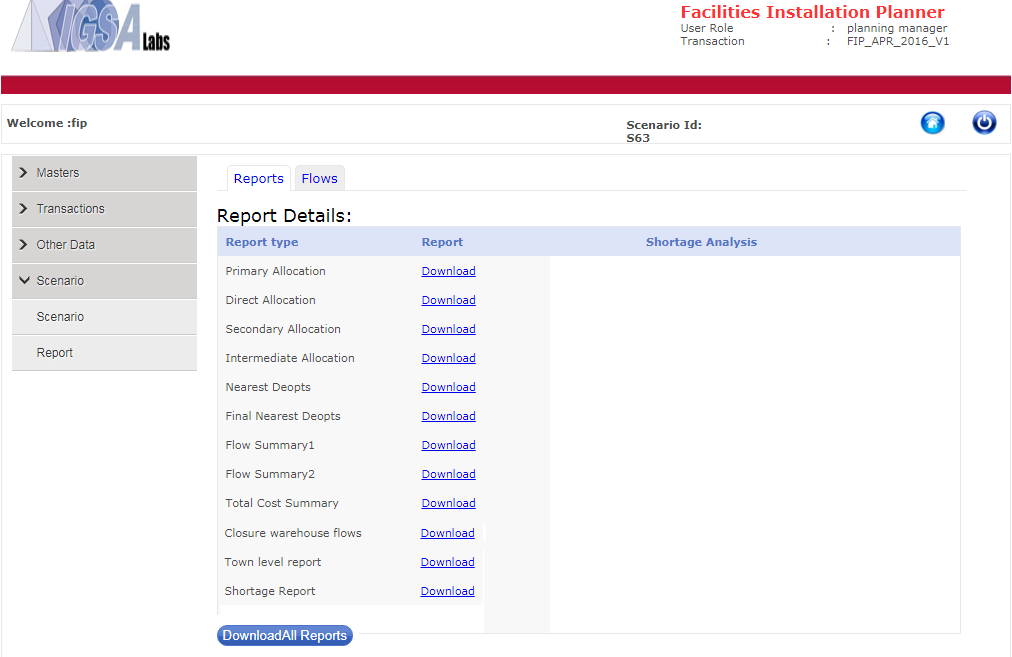

Create optimal supply chain network – locations and capacities of warehouses, channel partners, plants, transportations modes and links, and supplier facilities – in order to meet future targets for revenue growth, market expansion and diversification, profitability, and carbon neutrality

-

Achieve or exceed growth targets in the most profitable manner subject to meeting customer serviceability targets, opportunities and limitations for investing in new facilities and in expanding existing facilities for logistics and production in a multi-tiered supply chain network

-

Recommend most appropriate supply chain network structures for different product-market categories, including the mix of centralization and decentralization in inventory storage and production facilities, extent of ‘pull’ and ‘push’ supply chains, and placement of push-pull decoupling boundary

-

Run large scale mixed-integer linear programming model with millions of variables in quick time

-

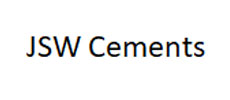

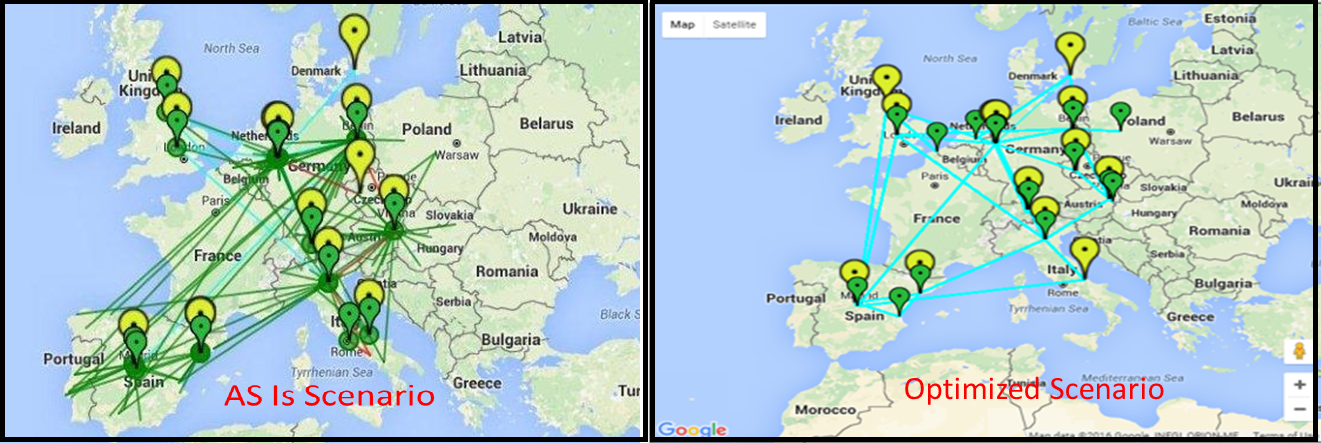

Facilitate ‘what-if’ analysis with multiple scenarios, including greenfield and brownfield network designs

-

Validate input data, resolve infeasibilities, and display violations of demand, serviceability, capacity and other constraints

-

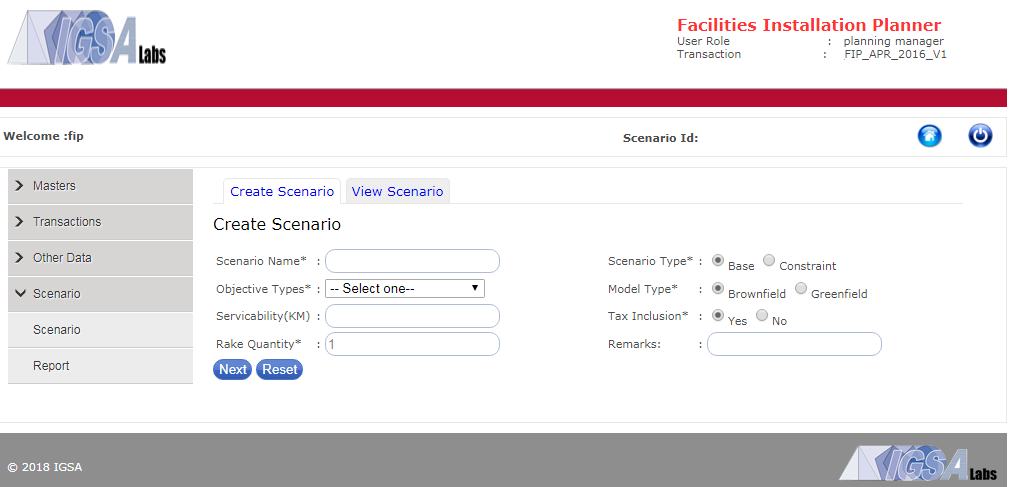

Report performance metrics such as contribution margin (EBIDTA), return on investment, sales revenue, demand fulfillment rate, cost-to-serve, utilization of production and logistics assets

-

Align sales and marketing, logistics, production, and procurement teams with common business objectives and facilitate inter-functional collaboration

Analytical Models and Techniques

-

Large-scale mixed-integer linear programming (MILP)

-

Algorithms for ‘what-if’ scenario analysis

Tools and Technologies

-

MILP models with GAMS and CPLEX

-

Input data interface with Java

-

Dashboards for reports and collaborative platform with Power BI and Java

Case Studies

Clients