What It Does:

-

Create optimal execution schedules of machine-wise production at plants and vehicle-wise dispatch from plants and warehouses to customers for serving actual customer orders, replenishment orders and forecasted orders over the short run, i.e. one-seven days horizon

-

Maximize business profit margin subject to meeting customer serviceability commitments, achieving high utilization of production and transportation assets, constraints on availability of machine capacities at plants, transport vehicles of various sizes on specific routes, and priorities of sales, marketing, logistics, and production teams

-

Run large scale mixed-integer linear programming model with millions of variables in quick time

-

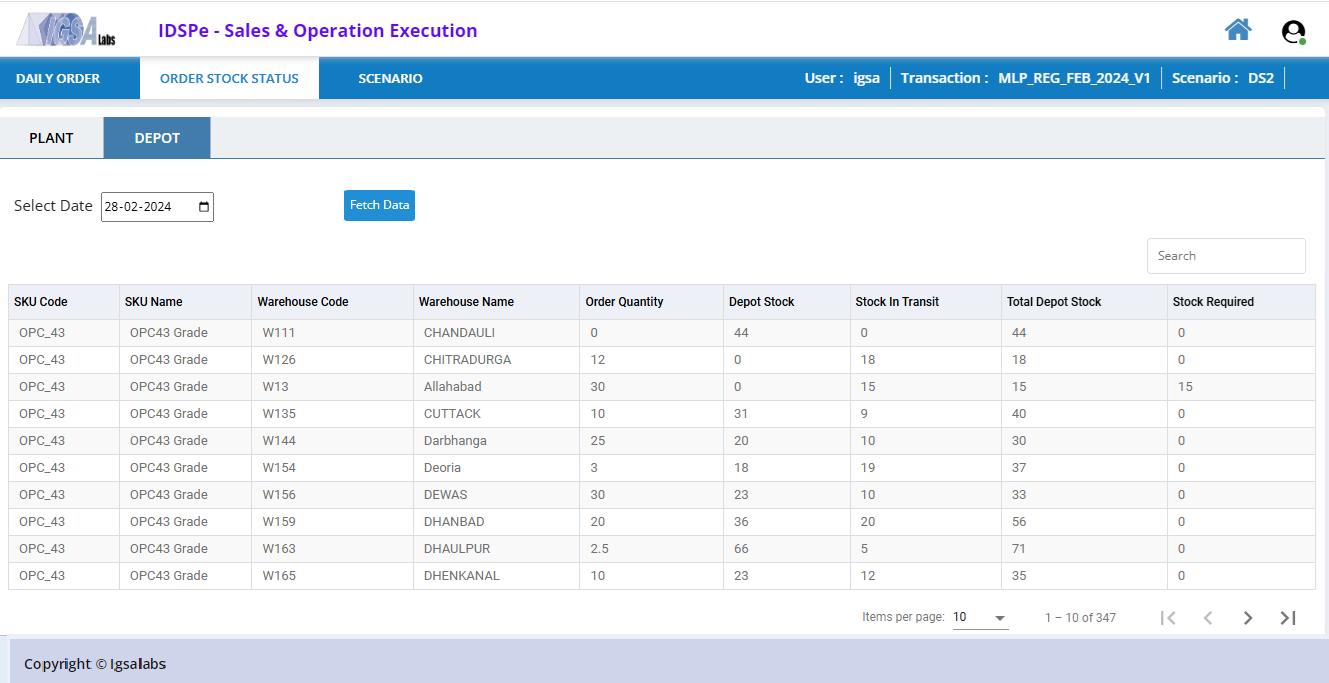

Facilitate ‘what-if’ analysis with multiple scenarios

-

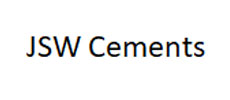

Validate input data, resolve infeasibilities, and display violations of demand, serviceability, capacity and other constraints

-

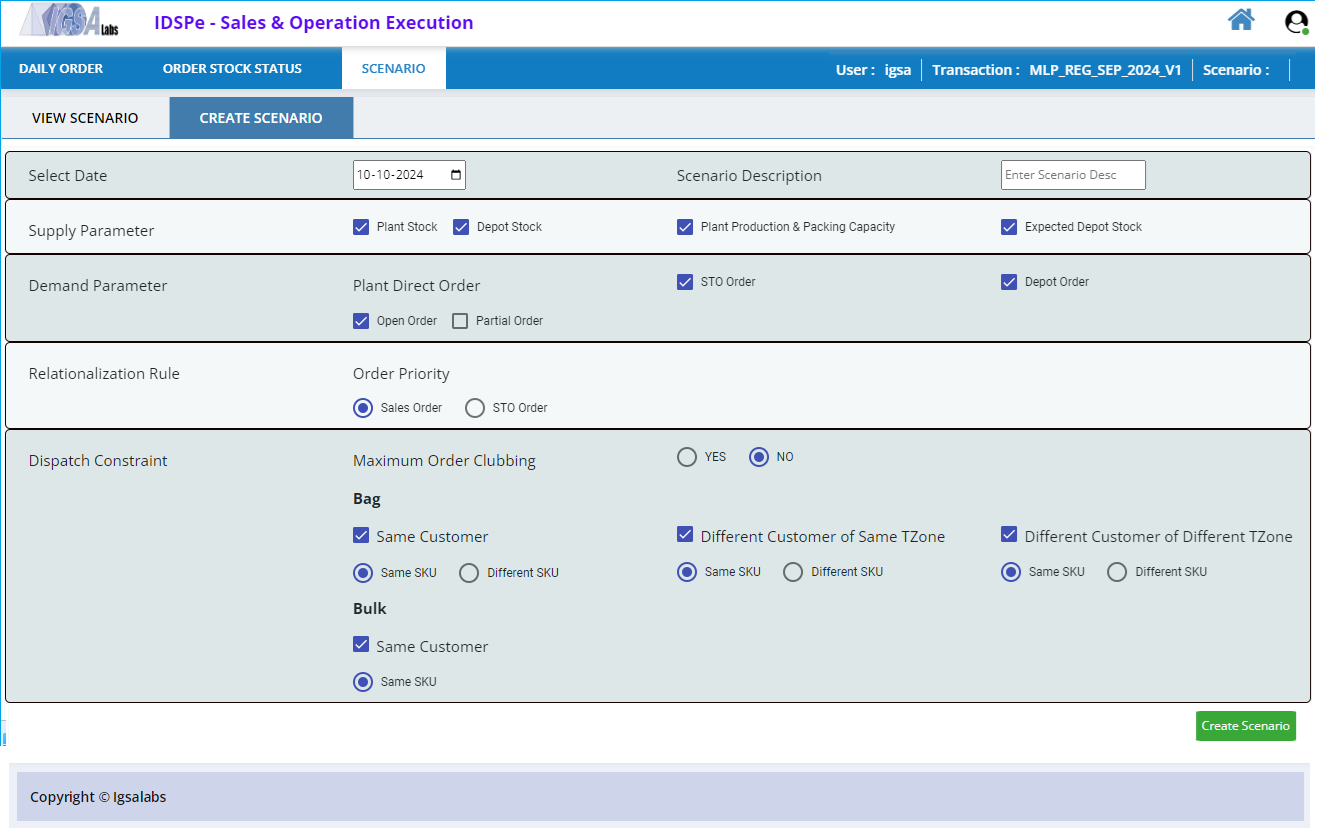

Report performance metrics such as contribution margin (EBIDTA), customer order fulfillment rate (OTIF), cost-to-serve, utilization of production and logistics assets

-

Align sales and marketing, logistics, and production teams with common business objectives and facilitate inter-functional collaboration

Analytical Models and Techniques

-

Large-scale mixed-integer linear programming (MILP)

-

Algorithms for ‘what-if’ scenario analysis

Tools and Technologies

-

MILP models with GAMS and CPLEX

-

Input data interface with Java

-

Dashboards for reports and collaborative platform with Power BI and Java

Case Studies

Clients