What It Does:

-

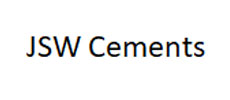

Decide optimal norms for order size, review period, reorder points, target stocks levels, and safety stocks for various classes of products/SKUs/raw materials at every warehouse/storage location, and generate orders according to continuous replenishment or periodic replenishment norms

-

Rationalize optimal orders based on practical constraints such as vehicle loadability and limited availability of products/SKUs/raw materials

-

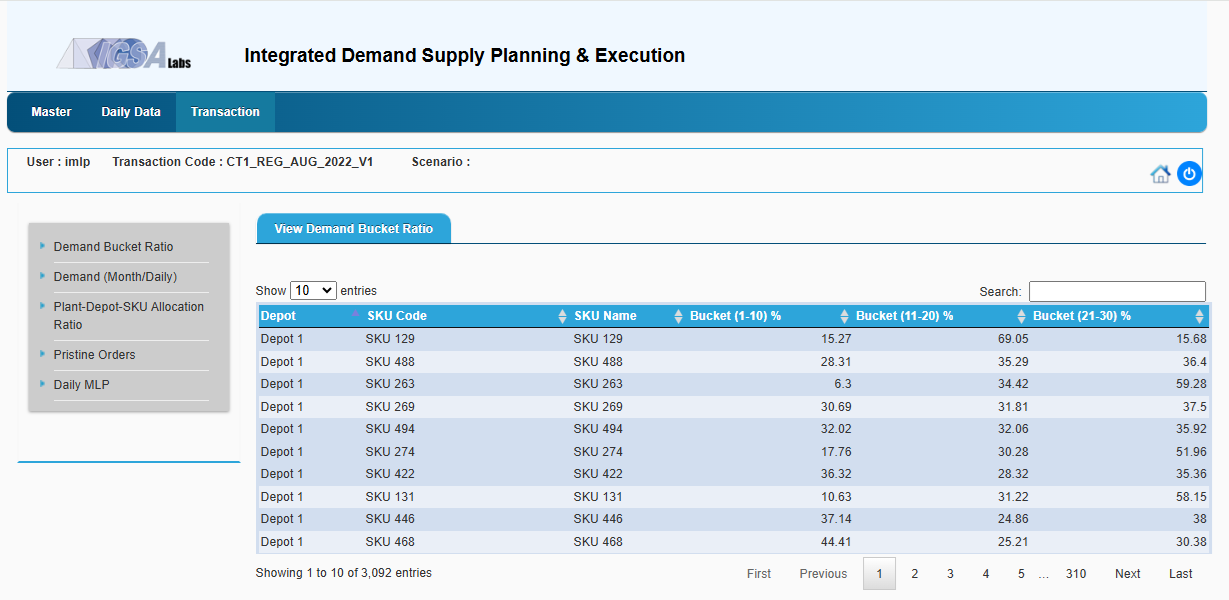

Meet desired customer service levels for various products/SKUs/raw materials while keeping inventory levels and transportation costs low

-

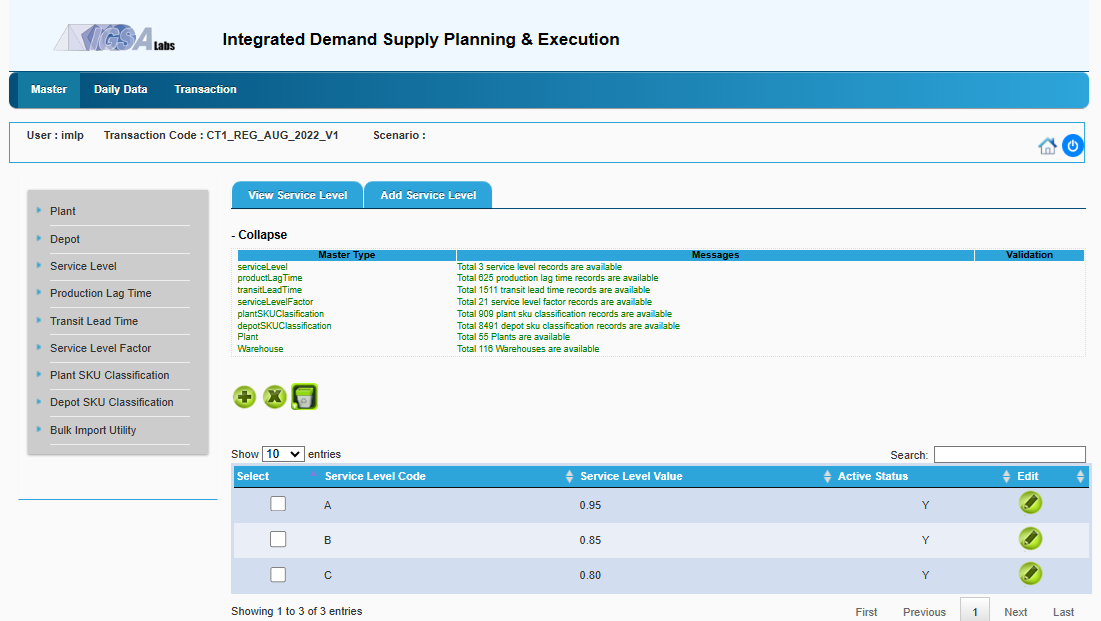

Minimize stockouts as well as excess stocks considering different priorities for different classes of products such as high value and low value, fast moving-stable demand and slow moving-variable demand, short- and long- shelf life

-

Validate input data and resolve infeasibilities

-

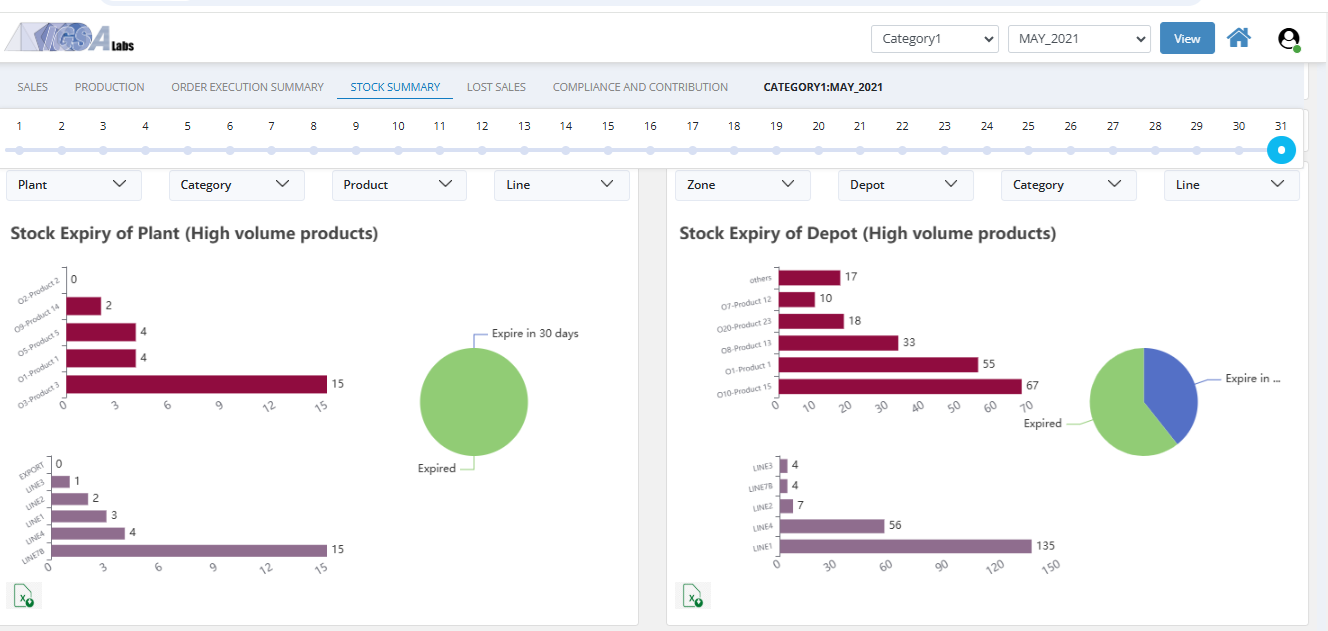

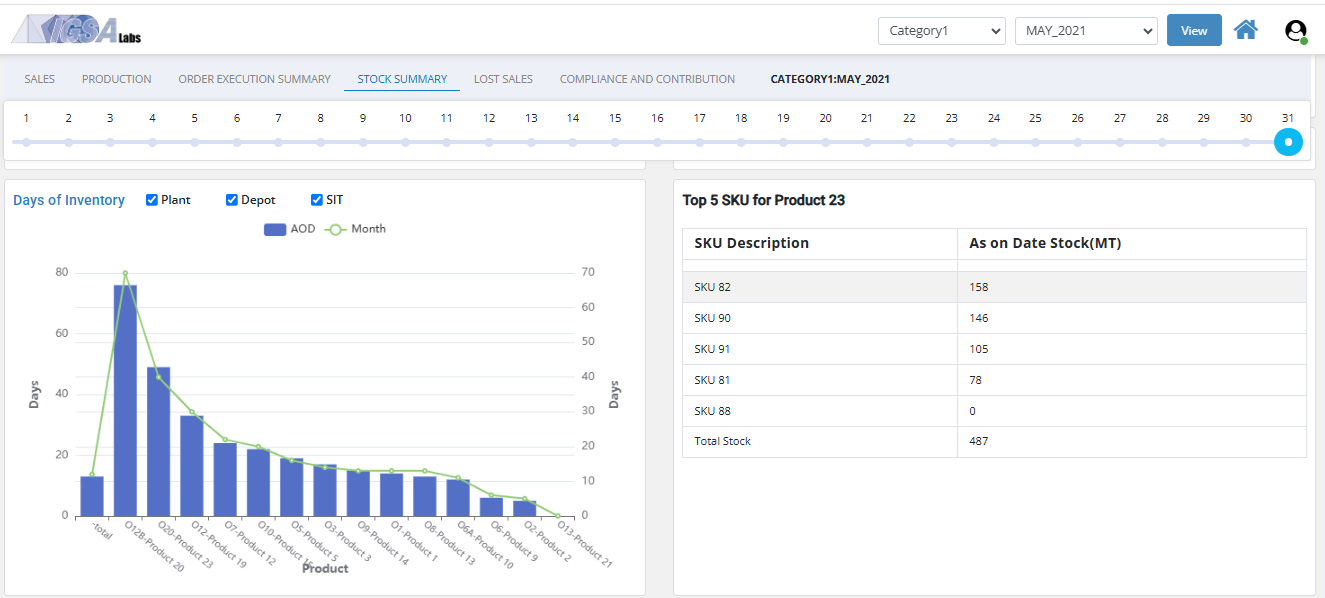

Report performance metrics such as customer service level (order fill rate, OTIF, stockout and lost sales), inventory levels and cost, transportation cost vehicle utilization, deviations from inventory norms

-

Align sales, logistics, production and procurement teams with common business objectives and facilitate inter-functional collaboration

Analytical Models and Techniques

-

Statistical and simulation models

-

Algorithms for ‘what-if’ scenario analysis

Tools and Technologies

-

Statistical and simulation models with Python

-

Input data interface with Java

-

Dashboards for reports and collaborative platform with Power BI and Java

Case Studies

Clients